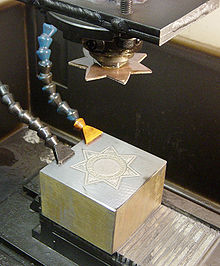

A CNC machine is a motorized maneuverable tool and often a motorized maneuverable platform, which are both controlled by a computer, according to specific input instructions.

A CNC machine is a motorized maneuverable tool and often a motorized maneuverable platform, which are both controlled by a computer, according to specific input instructions. CNC stands for "computer numerical control.” This versatile process accommodates various materials, including metals, plastics, wood, glass, foam, and composites.

CNC stands for "computer numerical control.” This versatile process accommodates various materials, including metals, plastics, wood, glass, foam, and composites.